Drilling rig RS-90 is made and produced in one of our production center of the company "RusMiningExport" in Russian city Khabarovsk.

The machine is manufactured in accordance with the quality standards of the world's best drilling equipment manufacturers. The design of the machine is similar to the LF-90, but with our original modifications.

Key benefits

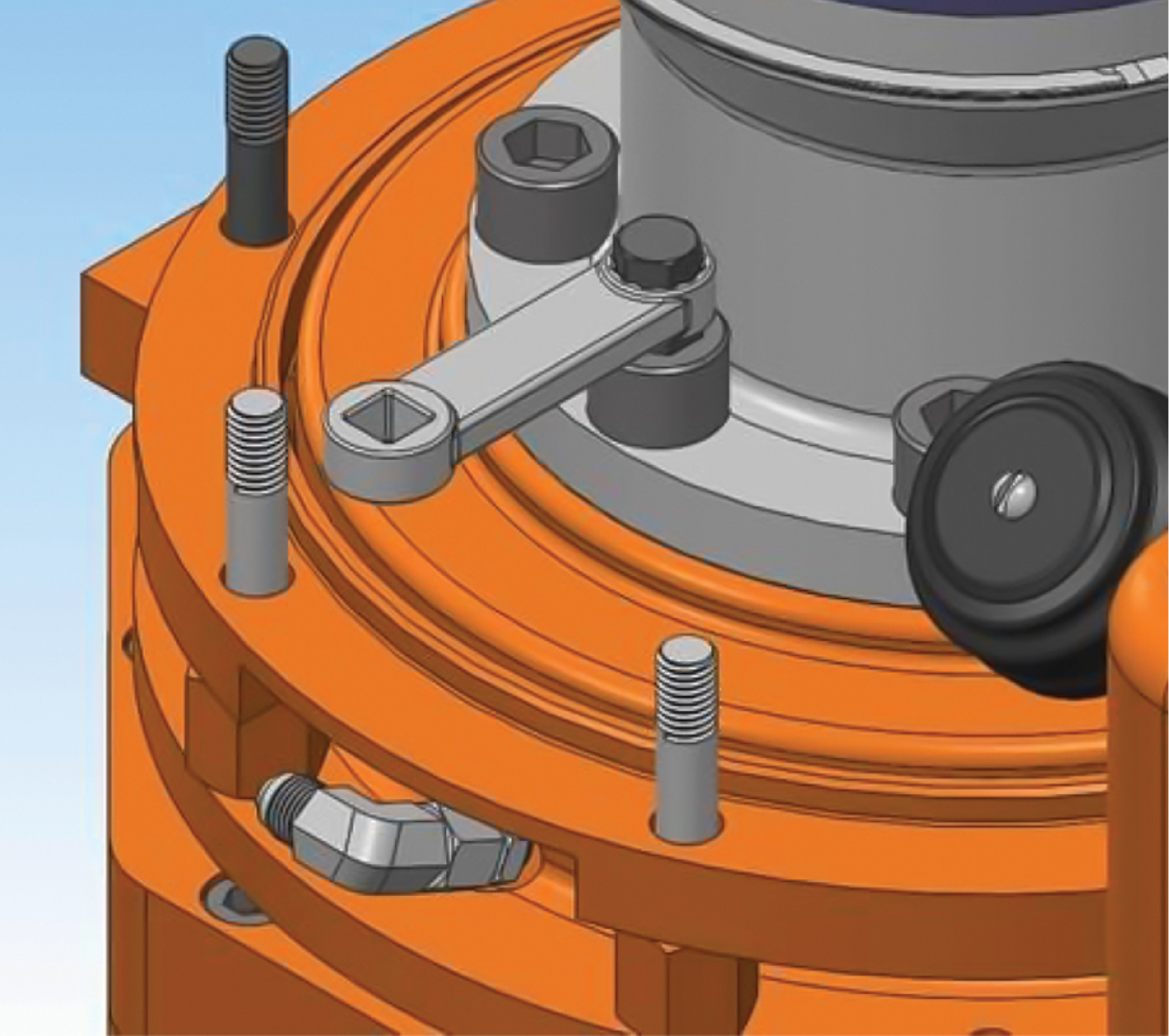

Full technical overviewUPGRADED DRILL HEAD

TO PREVENT OIL

CONTAMINATION

Drilling fluid can enter the drill head and the gear box through the top spindle seals. RME designed and manufactured drill head by special parts to prevent oil contamination on the RS 90.

LUBRICATION SYSTEM FOR

THE GEAR BOX

RME put the lubrication pump with higher capacity than standard pump RME implemented lubrication system by injectors (circled by red on the pictures). The lubrication system allows to lubricate gears, bearing and shafts with sufficient flow even on low rotation speed.

The lubrication system prevents overheating on low gears with low rotation speed while putting casing by high torque.

EASY ACCESS FOR THE BOX

OF RELAYS

RME designed special room for the box of relays near engine, so it helps to keep the relays dry and safe, and to have easy access for servicing.

REINFORCED MAST

The most stressed elements of the machine frame are reinforced.

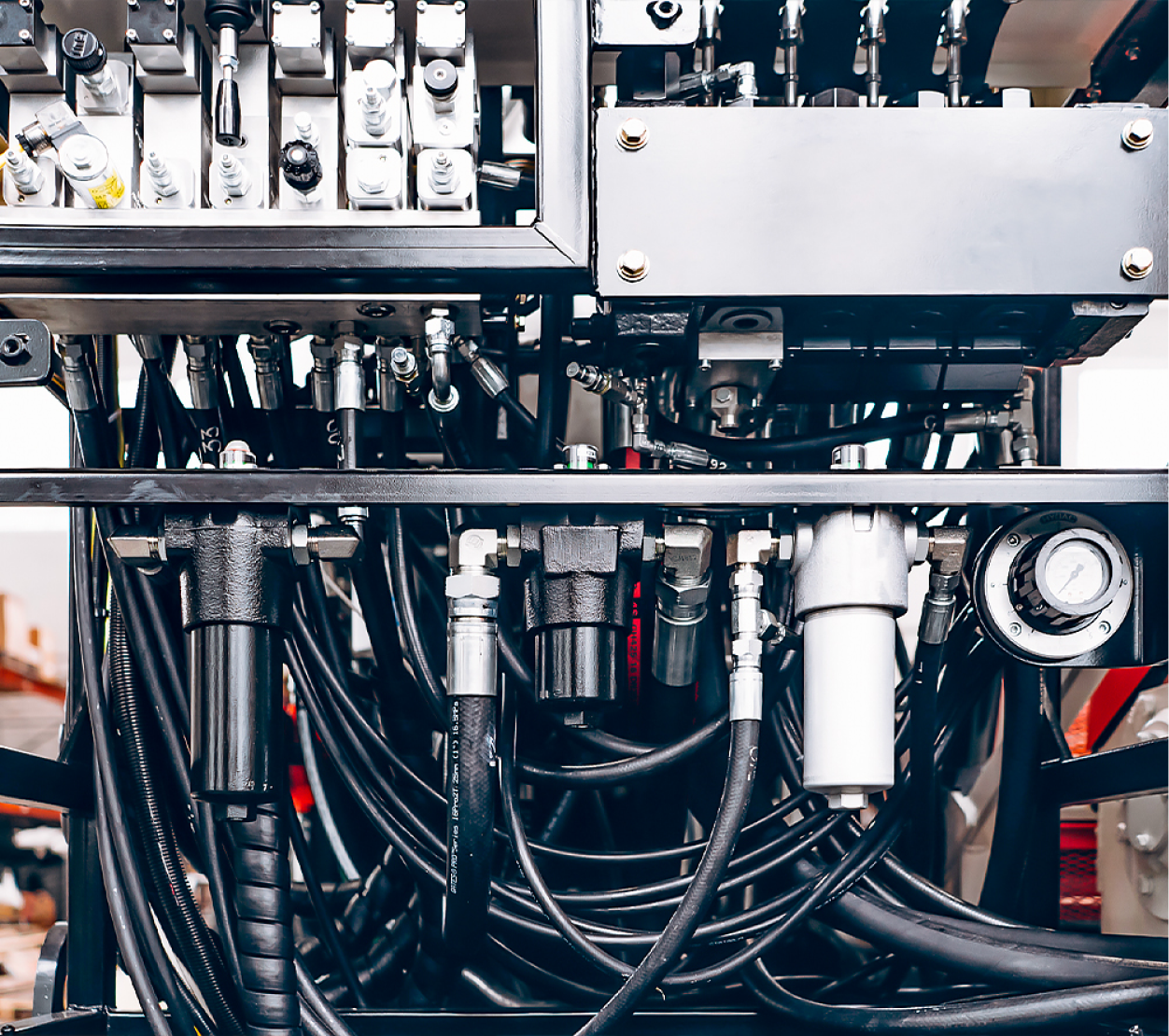

ADDITIONAL FILTRATION

SYSTEM

RME additionally builds a filtration system for secondary and auxiliary pumps and for lubrication system of the rotation unit. These filters are located under the control panel for easy access for servicing.

The additional system allows prolong pumps and the rotation unit’s life.

EASY ACCESS FOR SERVICING

RS90’s steel frame is extended for 20cm to have more space for easy access when servicing hydro components between the hydraulic tank and control panel extended.

TECHNICAL OVERVIEW

The RS90 is a compact drill rig weighing only about 5656kg.

The drill can be easily mounted on a towing group with hydraulic jacks and towed to remote locations to drill up to 1200m NWL V WALL.